Changshengqiao landfill is a typical valley-type waste disposal site with a land area of 690,642 m3, a landfill area of approximately 379,620 m3 and a design capacity of about 14 million m3. The landfill site was put into operation at the end of July 2003 and was shut down at the end of 2016. It has been undergoing regulated closure and restoration since 2018.

The existing leachate treatment facility at Changshengqiao Landfill is designed as a 1,730 ton/d facility, consisting of a 400 ton/d MBR+DTRO system and a 1,330 ton/d STRO emergency treatment system. Currently, the MBR+DTRO systems produces about 100 tons of leachate concentrate per day, and the STRO facility produces about 400 tons of concentrate per day. The produced leachate concentrate is mixed and stored in the equalization pool inside the landfill site, of which about 38,000 m3 are stored inside the landfill and about 140,000 m3 are stored outside the landfill. The storage capacity of the site is nearly saturated, with prominent environmental risks.

The leachate concentration treatment system in this project is mainly consisting of two concentrates, one is MBR+DTRO concentrate with advanced biochemical treatment, and the other is STRO concentrate without biochemical treatment. The water quality of the two concentrates differs greatly, and the treatment object of this project is mixed concentrate.

Complete leachate concentration treatment in the landfill within 3 months of official operation.

Complete leachate concentration treatment inside and outside the landfill within 18 months of official operation.

Processes new leachate concentrates simultaneously on a daily basis.

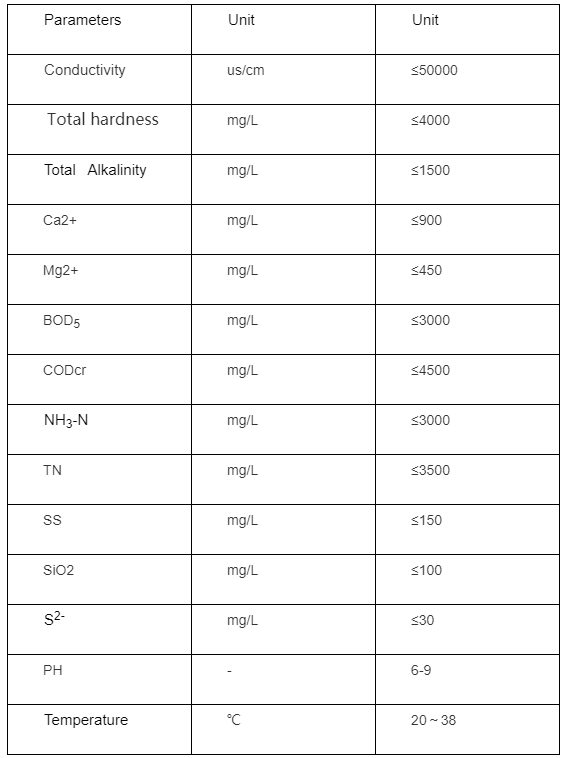

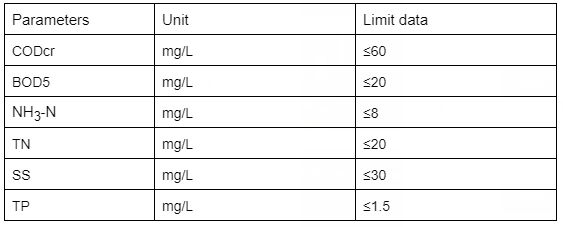

According to the water quality report of sampling water and the experience of our company in similar projects, the design feed water quality of this project is as follows:

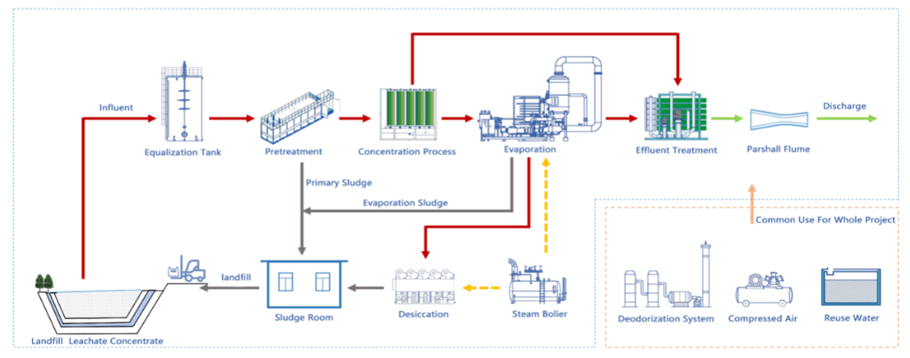

ZLD 1,000 m³/d treatment process

Pretreatment + Concentration + Evaporation +Desiccation

The concentrate in the equalization tank contains suspended solids(SS) and also has high hardness. Both of them need to be removed by softening and TUF pretreatment.

The effluent from softening is treated by the material membrane. The material membrane selection depends on the appropriate molecular weight. According to the experimental result, the suitable molecular weight can be decided. In this case, part of the colloid and macromolecular organic matters can be selectively rejected by the chosen material membrane without rejecting hardness and salinity. This can provide a good environment for HPRO and MVR operation. Besides, the system is capable of 90-98 % recovery with lower operating pressure due to the material membrane characteristics. Additionally, a small amount of concentrate is further treated by desiccation.

The effluent from the material memtrane is concentrated by HPRO. Since the HPRO adopted the anti-pollution disc membrane module, it can highly concentrate the raw water, reducing the amount of evaporated water. Hence, the overall investment and operation cost can be saved.

The permeate quality from the material membrane is good for reducing the amount of anti-foam agent used in the MVR evaporation system. This can effectively eliminate the foaming phenomenon. In addition, the salt cannot be wrapped by the organic matter, which is beneficial for the stable and continuous evaporation crystallization. Besides, since MVR system can operate in acidic conditions with negative pressure and low temperature, the scaling and corrosion phenomenon can be prevented. Also, the foam is hard to generate, leading to the good evaporation condensate quality. The MVR permeate flows back to the membrane system for further treatment before discharge. The brine from MVR is treated by desiccation.

There are three kinds of sludge generated in this project, which need to be treated. They are the inorganic sludge from pretreatment, the brine sludge from evaporation crystallization and the sludge from desiccation.

The contract was signed in November, 2020. The equipment with 1000 m³/d treatment capacity was installed and accepted in April, 2020. The Jiarong Changshengqiao concentration ZLD project can be regarded as the WWT industry benchmark.

Share your leachate data and discharge requirements. We'll help assess a feasible and stable treatment approach. No obligation. Technical discussion first.

SubmitPlanning or Upgrading a Landfill Leachate Treatment System?

Contact Us