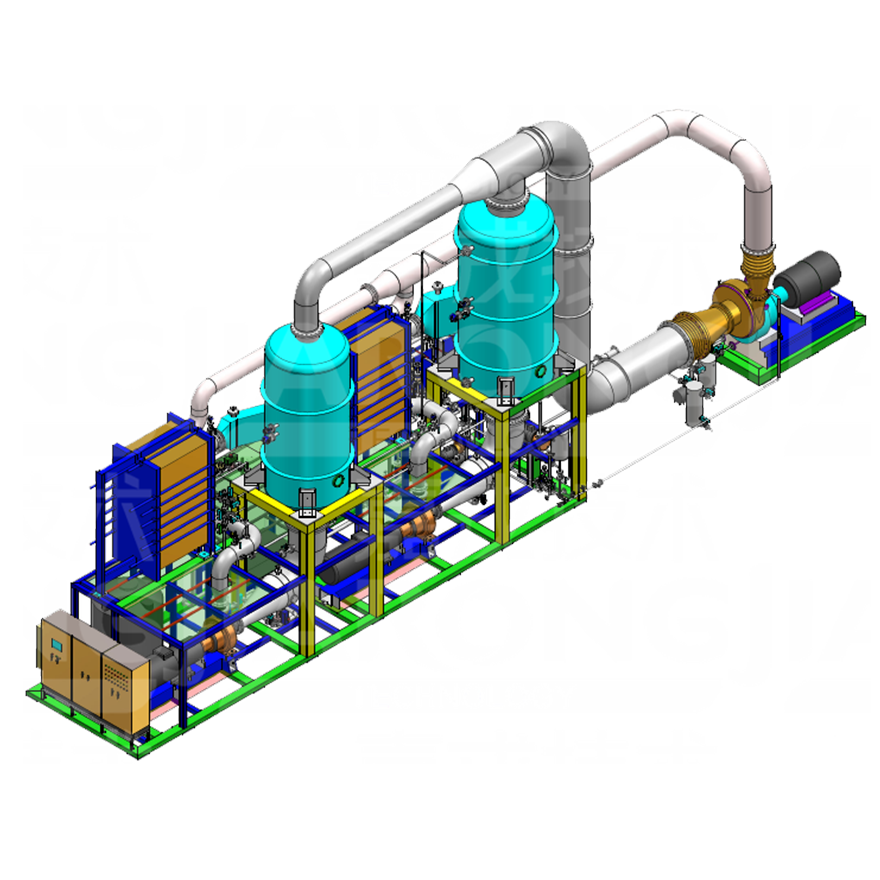

I-FLASH MVR is a high efficiency contamination-resistant evaporator for high salinity and difficult wastewater, independently designed and developed by Jiarong Technology. I-FLASH MVR features a multitude of advantages such as standard modular design, high-efficiency contamination resistance, and digital intelligent control.

Contact us Back1. Standard modular design

Fully integrated skid-mounted design with compact occupation, only half the height of conventional design.

Minimal construction requirements

Forecast-based inventory strategies of standard products to enable rapid delivery

Simple installation, quick on-site installation period, prevent cross-construction to ensure construction safety

2. Efficient contaminant resistance

High-flow forced circulation with excellent turbulence flushing effect

Separate the heat exchange surface from the evaporation surface,significantly reducing the risk of scaling and coking on heat exchange surface

Applicable for high viscosity and scaling-prone fluid

Patented wide flow path design provides high turbulence and high shear force to prevent scaling and fouling Suitable for high pollution load conditions

Significantly higher heat transfer efficiency than conventional tubular heat exchangers

3. Negative pressure low temperature evaporation

Negative pressure low temperature evaporation technology(evaporation temperature around 70℃),greatly improve permeate water quality

Noticeably reduce scaling and material corrosion trends, extending cleaning cycles and service life

Negative pressure condition effectively prevents secondary gas pollution

4. High-quality manufacturing with artisan spirit. Stable and superior performance

Adopt with corrosion-resistant titanium, 2507 special stainless steel materials

6S standard production line

5. Digital intelligent control

Advanced data-based cloud platform management

Real-time remote monitoring, failure analysis and risk warning in advance

PLC Intelligent control, one button start-up &shut-down, simple operation and maintenance

Comprehensive CIP online cleaning program to reduced manpower load and avoid offline manual cleaning

No | Technical Parameter | 50tMVR | 100tMVR | 200tMVR | 350tMVR |

1 | Capacity | 50-80 t/d | 100±10 t/d | 200±10 t/d | 350-400 t/d |

2 | Running Pressure | 31.2 kPa | 31.2 kPa | 31.2 kPa | 57.8 kPa |

3 | Evaporation Temperature | 70℃ | 70℃ | 70℃ | 85℃ |

4 | Typical Size | 10.5m×2.9m×8.3m | 10.5m×2.9m×8.3m | 21m×3m×9m | 12m×3m×10.5m |

5 | MVR Operating Power | 322 kW | 392 kW | 815 kW | 691 kW |

Share your leachate data and discharge requirements. We'll help assess a feasible and stable treatment approach. No obligation. Technical discussion first.

SubmitPlanning or Upgrading a Landfill Leachate Treatment System?

Contact Us