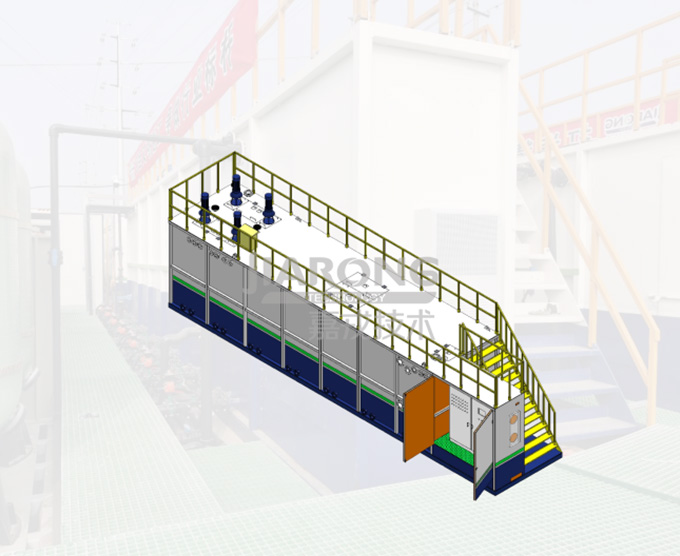

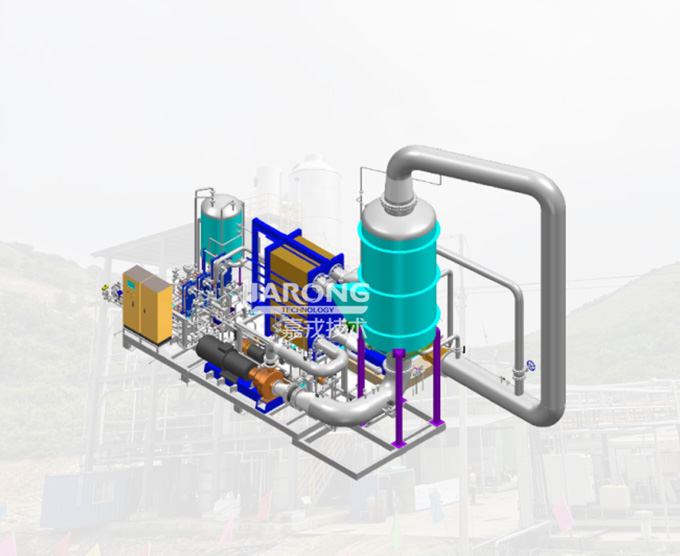

Jiarong ZLD comprehensive processing system comprises four sections including full pretreatment, high efficiency pre-concentration, evaporation, and desiccation/solidification. Jiarong ZLD equipments use standardized modular design, flexible assembly according to the practical water quality and different processes combinations.

Contact us BackFull pretreatment

Ensure the stability and reliability of evaporator operation

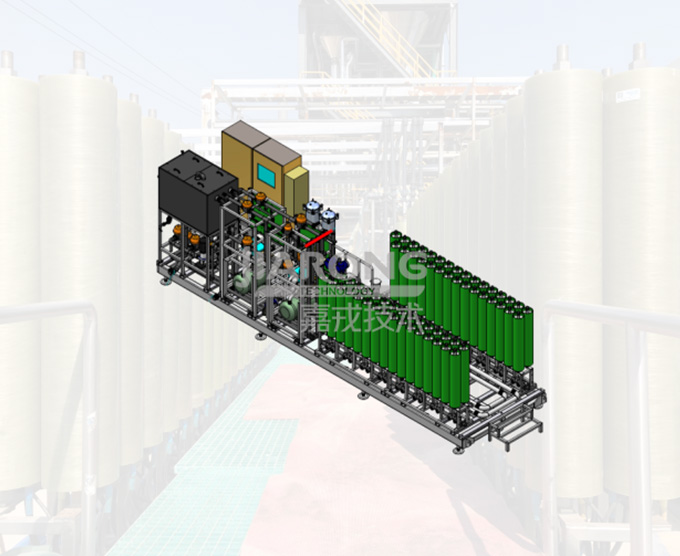

High efficiency pre-concentration

Reduce energy consumption and investment capital

I-FLASH MVR

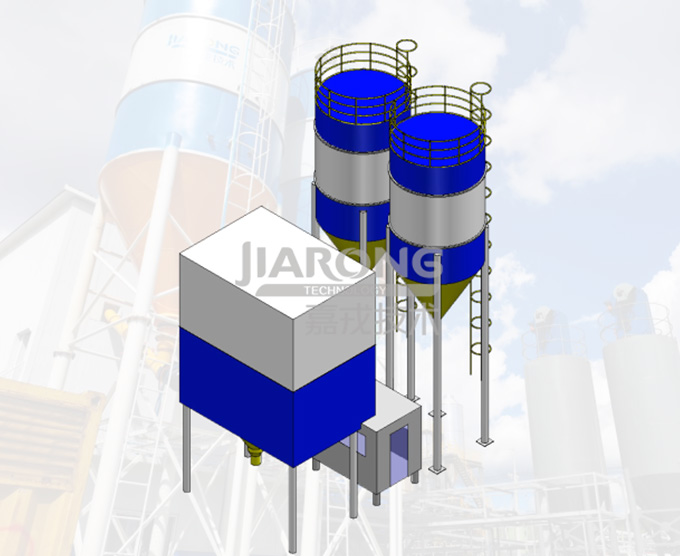

Desiccation/Solidification

Harmless treatment/landfill of leachate sludge

Coagulating sedimentation +TUF+DTRO+ Membrane Filtration (MF/UF) +MVR+ Desiccation

HPRO+MVR+Two-staged DTRO/Ion exchange+ desiccation/solidification

Consistent water quality and quantity of produced water in accordance with standards

High yield of permeate water, no residues

High degree of automatic control and excellent operational stability

Controllable Investment costs and operating costs

Integrated design with compact occupation

Corrosion-resistant, anti-scaling, easy to maintenance

Efficient contaminant-resistance

Eco-friendly treatment of sewage sludge

Hubei Leachate ZLD treatment project

The project is an important part of the integrated protection and restoration project of Honghu, which is constructed and operated by JIARONG Technology. The project has high water hardness, high sulfur content, high processing difficulty and tight construction time. After all the efforts of the project team, the project was completed and put into operation on schedule, and after the commissioning of the stable operation, the produced water meets the discharge standards, and the project has significant environmental benefits.

Capacity: 500-600 ton/day

Treatment Process: Concentration + Low-temperature MVR + Water Production Guarantee

Liaoning leachate ZLD treatment project

The water quality of this project has high COD and TDS, high ammonia nitrogen concentration and high sulfide content. JIARONG Technology overcame the cold conditions of winter construction, as well as the epidemic interference, tight schedule and other difficulties, and completed the project installation and put into operation on schedule, the main equipment is two 200 tons / day I-FLASH MVR evaporator, the equipment is running stably, and the produced water is stable and meets the standard.

Capacity: 1400 ton/day

Treatment Process: Pretreatment + Two-stage DTRO + HPRO + Low-temperature MVR + Water Production Guarantee + Solidification and landfill of remaining tailings

Guangxi leachate ZLD treatment project

The old landfill leachate treated in this project is complex and variable with high pollutant content. The ZLD treatment process provided by Jiarong is reliable to maintain stable operation with high efficiency and low energy consumption. Also, the produced water meets the discharge standard. The remaining residue are solidified and landfilled.

Capacity: 300 ton/day

Treatment Process: Pretreatment + Two-stage DTRO + HPRO + Low-temperature evaporation + Solidification

Chongqing leachate concentrate ZLD project

Leachate concentrate is characterized by high suspended solids and high hardness. Existing leachate treatment facility at Landfill is designed as a 1,730 ton/day facility, consisting of a 400 ton/day MBR+DTRO system and a 1,330 ton/day STRO emergency treatment system. Currently, the MBR+DTRO systems produces about 100 tons of leachate concentrate per day, and the STRO facility produces about 400 tons of concentrate per day. The produced leachate concentrate is mixed and stored in the equalization pool inside the landfill site, of which about 38,000 m3 are stored inside the landfill and about 140,000 m3 are stored outside the landfill. The storage capacity of the site is nearly saturated, with prominent environmental risks.

The contract was signed in November, 2020. The equipment with 1000 m³/d treatment capacity was installed and accepted in April, 2020. The concentration ZLD project can be regarded as the WWT industry benchmark.

Capacity: 1,000 ton/d

Treatment Process: Pretreatment + Concentration + Evaporation +Desiccation+ Deodorization system

Heilongjiang leachate ZLD treatment project

The landfill concentrate is treated in this project with the capacity of 200 tons per day. The variable concentrate has high concentration of salinity, hardness, ammonia and sulfide and so on and so forth. The ZLD treatment process has been adopted by this project. The MVR is provided by Jiarong Technology and the stable produced water can meet the standard. The remaining tailings are solidified and landfilled.

Capacity: 200 ton/d

Treatment Process: Softening pretreatment + Low-temperature MVR + Ion exchange/Spiral-wound membrane + Solidification and landfill of remaining tailings + Deodorization system

Solid R&D capabilities, exceptional technical team

In terms of technology R&D, Jiarong Technology always adheres to the strategy of having a full-spectrum technical team. From pre-treatment, membrane-led concentration and filtration, evaporation system to desiccation, each module is manned by senior specialists with extensive project experience. The project technical team has more than 300 projects experience in leachate treatment. We are able to customize the most adequate process solutions according to the actual situation of each project.

Share your leachate data and discharge requirements. We'll help assess a feasible and stable treatment approach. No obligation. Technical discussion first.

SubmitPlanning or Upgrading a Landfill Leachate Treatment System?

Contact Us