Xiamen Jiarong Technology Co., Ltd. is responsible for the design, construction, and operation of the Yuheng Industrial Zone Evaporation Pond Brine Treatment Project in Yulin City, Shaanxi Province (Section N2) . The project has a treatment capacity exceeding 1,440 tons per day. The evaporation and crystallization process is expected to produce 435,000 tons of water , with a construction period of approximately 540 calendar days (including a 180-day construction period ). This project is a typical large-scale, fully automated treatment project for high-salinity industrial wastewater and brine.

The project's original evaporation pond brine had a complex composition , containing various impurities and wastewater from previous treatment processes , resulting in a salinity of 10% to 20%. The project's effluent quality was required to meet the standards for "Urban Wastewater Reuse , Industrial Water Quality " (GB-T19923-2024) and "Urban Wastewater Reuse , Urban Miscellaneous Water Quality "(GB-T18920-2020),with a water conductivity of ≤800μS/cm. This project placed extremely high demands on the treatment system and equipment , coupled with a tight construction schedule , the large amount of equipment involved , and the complex civil engineering requirements.

Project process principle: pretreatment + evaporation reduction MVR + evaporation crystallization MVR + two-effect evaporation crystallization + mother liquor drying.

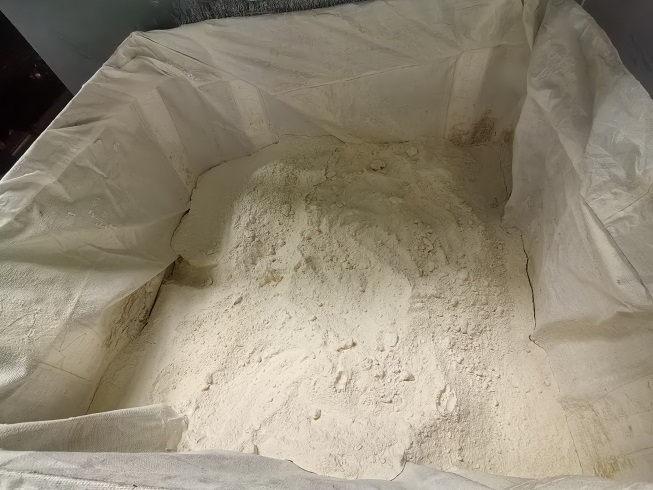

Raw water undergoes a two-stage pretreatment process of coagulation and sedimentation to remove silicon, fluorine, hardness, and some impurities. The pretreatment product enters the evaporation and reduction MVR. After concentration and reduction, it is processed in the evaporation and crystallization MVR. The treated mother liquor enters a two-effect evaporation and crystallization process. The evaporated mother liquor passes through a centrifuge to remove some impurities , and is finally transported to the mother liquor drying system for drying. The impurities produced by the evaporation, crystallization, and drying equipment are packaged and transported by forklift to the impurity salt storage warehouse. The evaporation condensate enters the product water quality assurance equipment for treatment , ensuring that the product water consistently meets the standards.

The core equipment of this project utilizes Jiarong Technology's independently developed low-temperature negative pressure MVR evaporation equipment. The project utilizes a modular design and installation system, boasting numerous advantages, including mature and stable technology, flexible configuration, and a high degree of automation. The project officially commenced operations in August 2025, achieving outstanding results. The project's water is being reused in the industrial park, with water quality far exceeding standard requirements. This not only addresses the environmental challenges and pain points of the park's concentrated brine evaporation ponds, but also conserves and reuses significant water resources, making a positive contribution to industrial production and ecological environmental protection efforts in Yulin City.

Create quality products, achieve customer success, and protect the environment. Jiarong Technology is down-to-earth and dedicated to contributing to the green mountains and clear waters of our motherland through innovation and practice.

Share your leachate data and discharge requirements. We'll help assess a feasible and stable treatment approach. No obligation. Technical discussion first.

SubmitPlanning or Upgrading a Landfill Leachate Treatment System?

Contact Us